Are you tired of hearing about this so-called “revolutionary” five-axis machine for contouring applications? Well, join the club. It seems like every industry expert and their grandmother can’t stop talking about it. But is it really as game-changing as they claim? Let’s take a closer look.

The Promised Advantages: Is It All Just Smoke and Mirrors?

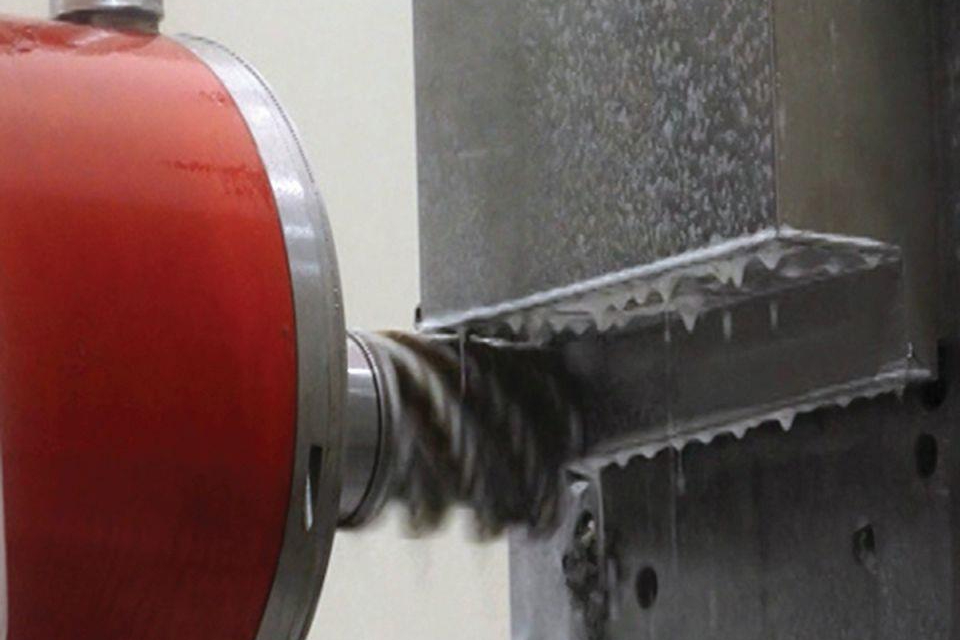

Proponents of the five-axis machine rave about its ability to increase productivity, improve accuracy, and reduce setup time. Sounds great on paper, right? But let’s be real here – how often do things actually live up to their hype? We’ve all been burned before by overpromising products that fail to deliver.

And what about cost? These machines don’t come cheap. Investing in a five-axis machine means shelling out a significant amount of money upfront. So, before jumping on the bandwagon, we need solid evidence that justifies such a hefty investment.

The Learning Curve: Will You Need an Engineering Degree?

If you’re not already familiar with CNC machining or have an engineering background, brace yourself for a steep learning curve. Operating a five-axis machine requires specialized knowledge and training that may not be readily available or easy to acquire.

So unless you’re willing to invest time and resources into mastering this complex technology, it might end up being nothing more than an expensive piece of machinery gathering dust in your workshop.

A Skeptic’s Perspective

In conclusion, while the idea of a five-axis machine for contouring applications may sound enticing at first glance, there are several factors worth considering before taking the plunge. The promised advantages must be thoroughly evaluated against potential drawbacks such as cost, training requirements, and the actual impact on productivity.

So, before you get swept away by the hype surrounding this machine, take a step back and critically assess whether it’s truly worth your time and money. After all, in a world full of overhyped gadgets and gizmos, skepticism can be your best friend.