In the ever-evolving world of manufacturing, precision and efficiency are paramount. The latest advancements in machining technology have paved the way for enhanced productivity and superior results. One such breakthrough is the updated five-axis horizontal machining center (HMC), which has revolutionized aluminum machining processes.

A New Era of Precision

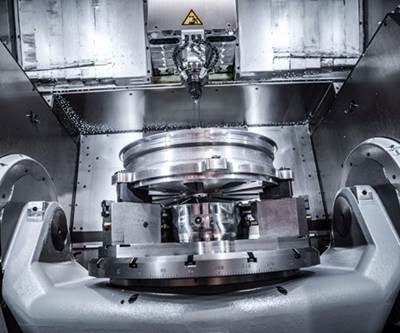

This cutting-edge five-axis HMC boasts a plethora of features that enable unparalleled precision in aluminum machining. Equipped with advanced control systems and state-of-the-art software, it offers an unprecedented level of accuracy, ensuring every intricate detail is flawlessly executed.

The incorporation of high-speed spindles further enhances its capabilities by enabling rapid material removal rates without compromising on surface finish quality. This allows manufacturers to optimize production cycles while maintaining exceptional part integrity.

Furthermore, the machine’s robust structure minimizes vibrations during operation, guaranteeing stability even when executing complex multi-axis movements. This eliminates any potential deviations or errors that may arise from external factors, resulting in consistently precise outcomes.

Unmatched Efficiency

The updated five-axis HMC sets new benchmarks for efficiency in aluminum machining applications. Its innovative design facilitates simultaneous multi-sided operations, significantly reducing setup times and maximizing throughput.

With its expanded tool magazine capacity and automatic tool changers, this cutting-edge machine ensures uninterrupted workflow by swiftly transitioning between various tools required for diverse operations. Additionally, integrated coolant systems efficiently dissipate heat generated during high-speed cutting processes to maintain optimal operating conditions throughout extended production runs.

To further enhance productivity gains, intelligent automation features streamline workflows by automating repetitive tasks such as workpiece loading/unloading and tool changeovers. This not only saves valuable time but also reduces human error risks associated with manual interventions.

Achieving Superior Results

The updated five-axis HMC’s ability to machine aluminum with unparalleled precision and efficiency translates into superior end results. The combination of its advanced control systems, high-speed spindles, and robust structure ensures exceptional surface finish quality while meeting tight tolerances.

Moreover, the machine’s versatility allows for intricate contouring and complex geometries to be effortlessly achieved. This opens up new possibilities in design innovation, enabling manufacturers to push boundaries and deliver products that surpass customer expectations.

By harnessing the power of this cutting-edge technology, manufacturers can unlock a competitive edge in the market by delivering top-quality aluminum components efficiently and reliably.

A New Era of Aluminum Machining

In conclusion, the updated five-axis HMC has ushered in a new era of precision and efficiency in aluminum machining. Its advanced features enable unmatched accuracy, enhanced productivity, and superior results. With this revolutionary technology at their disposal, manufacturers can elevate their capabilities to meet the ever-increasing demands of modern manufacturing industries.